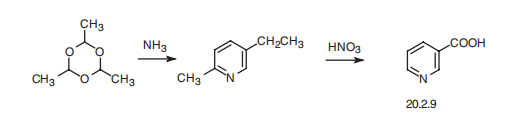

Nicotinic acid synthesis

- Product Name:Nicotinic acid

- CAS Number:59-67-6

- Molecular formula:C6H5NO2

- Molecular Weight:123.11

108-99-6

329 suppliers

$9.00/5g

59-67-6

1111 suppliers

$7.00/25g

Yield:59-67-6 99.58%

Reaction Conditions:

with oxygen;V2O5/Sb2O3-TiO2 in water at 260 - 280;Industry scale;Inert atmosphere;Gas phase;

Steps:

8

The catalyst was prepared by the method as described in Example 3 and process conditions were maintained as per Example 5 except that the process was carried out at large scale. The catalyst was packed as per Example 5 in a tubular reactor. Total volume of the reactor was 75 liters and equipped with heating and cooling arrangement. The catalyst bed was heated in the presence of air/nitrogen to 250° C. β-picoline, water and air were fed separately through a vaporizer from top of the reactor. The molar feed ratio of oxygen:water:β-picoline was 20:40:1 and WHSV was 0.05 hr-1. The nicotinic acid was isolated by the method as described in Example 4. The vent gases and scrubbed liquid obtained from secondary absorber and mother liquor of first absorber was recycled back in the process with optimum purge. The nicotinic acid obtained was white colored. Selectivity: 90.8%; β-picoline conversion of 94.6%. Assay: 99.58%.

References:

US2012/65405,2012,A1 Location in patent:Page/Page column 5

100-55-0

397 suppliers

$8.00/5g

59-67-6

1111 suppliers

$7.00/25g

1312414-21-3

0 suppliers

inquiry

59-67-6

1111 suppliers

$7.00/25g

350-03-8

649 suppliers

$10.00/5g

59-67-6

1111 suppliers

$7.00/25g

2398-81-4

192 suppliers

$5.00/5g

59-67-6

1111 suppliers

$7.00/25g