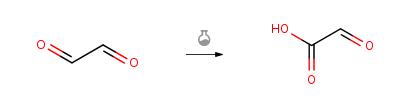

Glyoxylic acid synthesis

- Product Name:Glyoxylic acid

- CAS Number:298-12-4

- Molecular formula:C2H2O3

- Molecular Weight:74.04

108-31-6

846 suppliers

$13.47/50g

298-12-4

452 suppliers

$5.00/25g

Yield:298-12-4 98.3%

Reaction Conditions:

Stage #1: maleic anhydridewith water in methanol;ethyl acetate at 65; for 0.833333 h;

Stage #2: with ozone in methanol;ethyl acetate at 5; for 3 h;Solvent;Temperature;Time;

Steps:

1 Example 1

a. Melt 19.6120g of maleic anhydride in hydrolysis reactor. Heat in water bath. Add 5mL steam distilled water+5mL methanol+10mL ethyl acetate and undergo hydrolysis. Hydrolysis temp 65C, hydrolysis time 50min. b. After hydrolysis, transfer hydrolysate in self-made bubbling reactor. Supply with 5mL methanol+10mL ethyl acetate mixed solvent. Undergo ozonolysis. Ozone was bubbled from the bottom of the maleic acid solution so that ozone and the solution can completely come in contact. Control reaction temperature 5C, time 3h. c. At the end of the ozone oxidation phase, the passage of ozone was stopped and the residual ozone of the system was purged for 10 min. d. The reaction solution was slowly added to 8% sulfuric acid solution, and the control system temperature was 55 to 65 °C. e. After all addition, about a certain amount of CaO was added slowly, followed by the addition of 5 mL of water and the temperature was below controlled to below 10 ° C. Thereafter, the solution was allowed to stand to precipitate and the CaSO4 precipitate was removed by filtration to give a pale yellow solution. f. The resulting solution was transferred to a three-necked flask and several zeolites were added. In a 55C water bath, undergo vacuum distillation. Control pressure at 4.7kPa. Always observe the temperature of the solution, the control temperature should not exceed 55 .When the temperature of the solution is constant, stop heating. The distilled out formic acid and the mixed solvent are returned to step a for reuse. g. At the end of the vacuum distillation, the remaining solution was crystallized and cooled at 5 ° C for 3 days. h. glyoxylic acid product undergoes testing. Melting point of the product is 52.5C, yield is 98.3%. By liquid chromatography analysis of production, the purity of the product is 98%.

References:

CN106431885,2017,A Location in patent:Paragraph 0068; 0069; 0070; 0071; 0072; 0073; 0074-0121

131543-46-9

0 suppliers

inquiry

298-12-4

452 suppliers

$5.00/25g

110-16-7

720 suppliers

$10.00/5g

7722-84-1

5 suppliers

$24.46/*2x50ml

298-12-4

452 suppliers

$5.00/25g

91-20-3

509 suppliers

$14.00/25g

497-16-5

1 suppliers

inquiry

7722-84-1

5 suppliers

$24.46/*2x50ml

298-12-4

452 suppliers

$5.00/25g

107-21-1

1334 suppliers

$10.00/25g

50-00-0

864 suppliers

$10.00/25g

79-14-1

784 suppliers

$6.00/25g

141-46-8

33 suppliers

inquiry

298-12-4

452 suppliers

$5.00/25g