4-(4-Fluorobenzoyl)butyric acid synthesis

- Product Name:4-(4-Fluorobenzoyl)butyric acid

- CAS Number:149437-76-3

- Molecular formula:C11H11FO3

- Molecular Weight:210.2

108-55-4

436 suppliers

$6.00/25g

462-06-6

416 suppliers

$10.00/5g

149437-76-3

371 suppliers

$8.00/10g

Yield:149437-76-3 95%

Reaction Conditions:

with hydrogenchloride;aluminum (III) chloride in dichloromethane;water at 0; for 0.25 h;Friedel-Crafts Acylation;

Steps:

1.1; 1.2; 1.3; 1.4 Example 1:

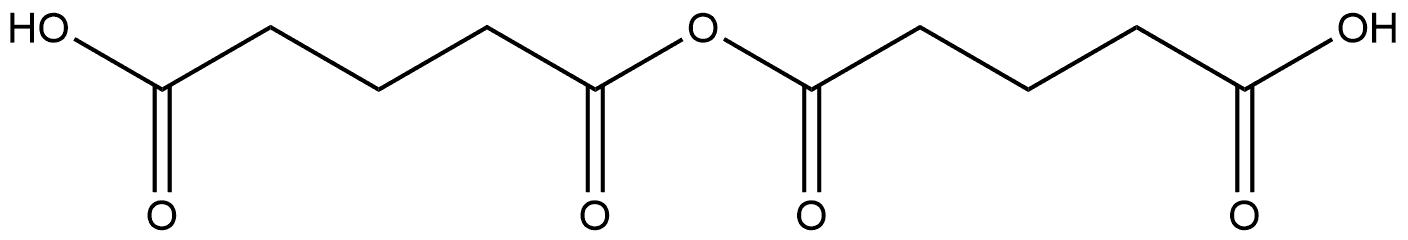

(1) Glutaric anhydride (compound 2) and fluorobenzene (compound 1) are uniformly mixed to obtain a homogeneous A solution. The concentration of glutaric anhydride (compound 2) in the homogeneous A solution is 1.5 mol/L. (2) Anhydrous aluminum trichloride, fluorobenzene (compound 1) and dichloromethane are mixed uniformly to obtain a homogeneous B solution. The concentration of aluminum trichloride in the homogeneous B solution is 0.75 mol/L. The molar ratio of aluminum to fluorobenzene (compound 1) is 1:1.7. (3) Dilute concentrated hydrochloric acid with water to make C solution, the concentration of hydrochloric acid in C solution is 1mol/L. (4) The first micro-reaction mixer M1 and the first reaction module L1 are both placed at a preset temperature, and the homogeneous A solution obtained in step (1) and the homogeneous B solution obtained in step (2) are combined The first advection pump P1 and the second advection pump P2 are respectively pumped into the first micro-reaction mixer M1 according to the flow rate ratio (1:2), and the first advection pump P1 pumps the above homogeneous A solution into the first micro-reaction mixing In the reactor M1, the flow rate is 0.2mL/min, and the mixture is evenly mixed and transferred to the first reaction module L1 (inner diameter: 0.1mm, length: 20m) for Friedel-Crafts acylation reaction. The reaction temperature is 0°C and the reaction time is 15min. The second micro-reaction mixer M2 and the second reaction module L2 are also placed at a preset temperature. After the Friedel-Crafts acylation reaction is completed, the obtained reaction solution (labeled as D reaction solution) is pumped into the second In the reaction mixer M2, the flow rate is 0.1mL/min, and at the same time, the C solution is pumped into the second reaction mixer by the third advection pump P3 according to the flow rate ratio (2:1) of the above D reaction solution. In M2, the mixture is uniformly mixed and transferred to the second reaction module L2 (inner diameter: 1 mm, length: 5 m) for quenching reaction, the reaction temperature is 0° C., and the reaction time is 10 min. The reaction liquid obtained after the quenching reaction is pumped into the receiving reactor R, Stir for 5 minutes, flow out through the liquid outlet O, and collect in the liquid separator, Let stand for liquid separation, extract the upper aqueous phase with dichloromethane, combine the organic phases, Add an equal volume of saturated sodium carbonate solution to alkalize, extract and separate liquids, The resulting aqueous phase was acidified with concentrated hydrochloric acid to its pH value of 1. After extracting the aqueous phase with dichloromethane, the organic phases were combined, Wash with saturated brine, dry with anhydrous sodium sulfate, filter with suction, After concentration under reduced pressure, vacuum drying for 12h at 35, 4-(4-fluorobenzoyl)butyric acid was obtained as a white solid with a yield of 95%.

References:

CN112778117,2021,A Location in patent:Paragraph 0041-0046

53715-97-2

0 suppliers

inquiry

149437-76-3

371 suppliers

$8.00/10g

108-55-4

436 suppliers

$6.00/25g

352-13-6

195 suppliers

$40.00/50mL

149437-76-3

371 suppliers

$8.00/10g