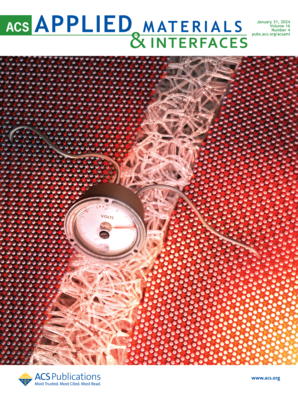

Constructing High-Performance Yarn-Shaped Electrodes via Twisting-after-Coating Technique for Weavable Seawater Battery

Abstract

Seawater batteries (SWBs) are green aqueous power sources with great potential in marine applications. So far, SWBs are mainly built on rigid substrates, which hinders their adaptability to marine textile applications. Herein, we constructed a rechargeable yarn-shaped SWB consisting of nickel hexacyanoferrate (Ni-HCF)-modified carbon yarn (positive electrode), glass fiber diaphragm, and polyimide (PI)-modified carbon yarn (negative electrode). To improve the performance of carbon yarn-based electrodes, a twisting-after-coating (TAC) technique was developed to replace the conventional twisting-before-coating (TBC) technique for immobilizing active materials. The TAC technique could fully utilize the internal spaces between adjacent fibers in carbon yarns and avoid the accumulation of active materials on the electrode surface. Taking the Ni-HCF-modified electrode as an example, its maximum specific capacity could reach 64.2 mAh/g, significantly higher than that (54.5 mAh/g) of the electrode prepared by the TBC technique. The improvement could be explained by embedding the active materials in the yarn and the close contact between the active materials and the carbon fibers caused by the twisting. The Ni-HCF-modified and PI-modified yarn electrodes prepared by the TAC technique were assembled to construct a yarn-shaped SWB that exhibits good rate performance, excellent flexibility, and high cycling stability. The yarn-shaped SWBs were further woven into a fishing net-like textile. After being soaked with seawater and electrically charged, the textile can successfully power a light panel composed of 10 light-emitting diodes, demonstrating the potential of yarn-shaped SWBs for power supply in marine.