| 93.03% |

With potassium hydroxide; In ethanol; for 4h;pH 9;Reflux; |

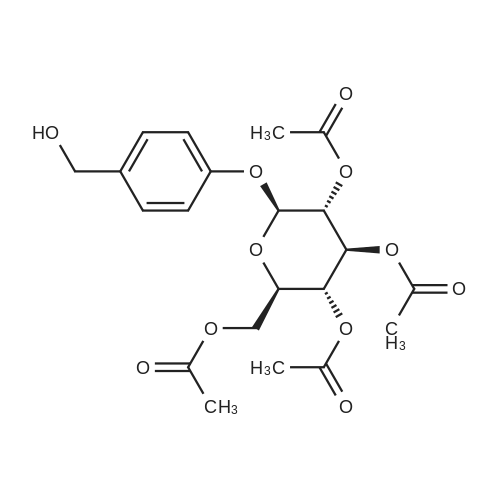

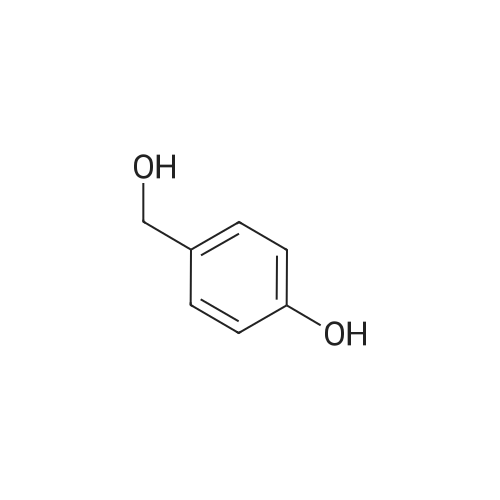

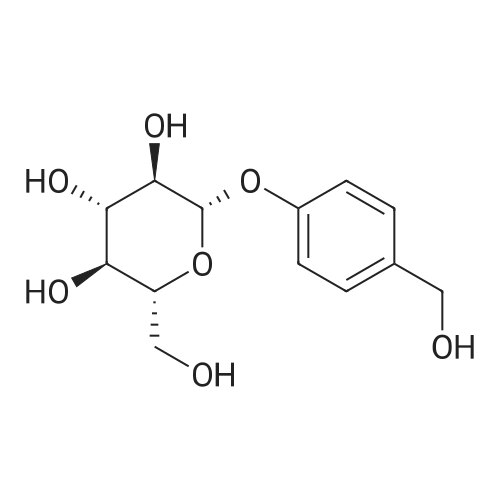

4.98 mg of ethanol was added to 0.98 kg of acetylconrodin,Add potassium hydroxide to adjust and maintain the system rhoH- = 9, after 2h reaction to stop the reaction, concentrated to 2.4L, add 4.85L of ethanol, reflux reaction 2h after the reaction to stop the reaction with TLC concentration solution; The total volume of the solution is 3.23L, 0.5 times the volume of ethyl acetate is added to the concentrate, and the resulting solid is dried to obtain 0.59kg of the crude extract of gastrodin, the yield is 92.65%; the filtrate is the mother liquor b, A mixed solvent of ethanol and ethyl acetate in a ratio of (alcohol: ester = 1: 1 (v / v)): gastrodin = 8: 1 (V / W) was added to the crude 0.59 kg of gastrodin, The mixture is heated to completely dissolve; filter impurity, the filtrate cooling after precipitation of crystals, to obtain pure gastrodin 0.518kg, the yield of 87.80%; filtrate for the mother liquor C, recovery reserve;The crude liquid b and the mother liquor c concentrated, filtered and dried to obtain the crude extract of gastrodin 0.097kg; 0.097kg in the crude extract of paclitaxel by adding 0.39L methanol, the mixture heated to completely dissolve; filter impurity, the filtrate cooled after precipitation of crystals, Product gastrodin 0.087kg, the yield of 13.66%And finally get pure gastrodin 0.605kg, the total yield of 93.03%. |

| 90% |

With methanol; sodium methylate; In water; at 20℃; for 5h;Inert atmosphere; |

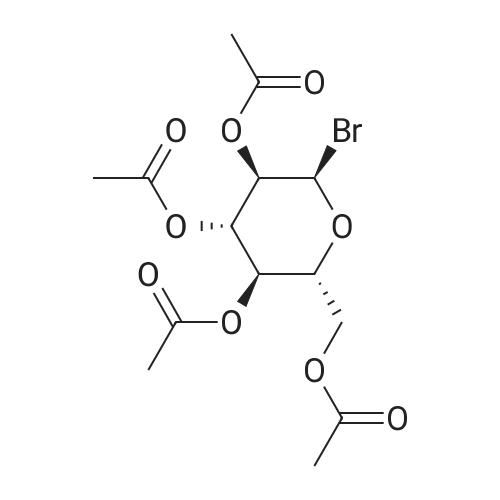

Sodium methoxide (200muL, 1 M in MeOH) was added to a solution of 5 (9.92 g, 0.020 mol) in 100 mL dry methanolunder a nitrogen atmosphere. The reaction mixture was stirred at room temperature for 5 hfollowed by neutralization with Amberlite IR 120(H+). Then the reaction mixture was filtered,and the resulting filtrate was evaporated to dryness under vacuum. Finally, recrystallization ofthe crude product from methanol-chloroform (1:8, V/V) yielded 5.21 g of the desired compound1 as white crystals. Yield: 90 % |

| 55g |

With diethylamine; In methanol; for 2h;Reflux; |

After 300 g of ethyl acetate was put into the reactor, 50 g of potassium triacetoxyborohydride was put into the reactor,Then, 100 g of 4-formylphenyl-2,3,4,6-tetra-O-acetyl-beta-D-glucopyranoside was charged,Temperature control in 20 to 30 insulation reaction,Samples were monitored by TLC,Reaction 1 hour reaction is complete,The reaction was quenched by adding the reaction solution to 300 ml of water,And then take the upper organic phase,The organic phase was concentrated to a solid under vacuum,Then, 300 g of methanol and 22 g of diethylamine were added and refluxed for 2 hours,Samples were monitored by TLC,After completion of the reaction, 10 g of activated carbon was added for 10 minutes,filter,The filtrate was concentrated to one third of the original volume,Then, 300 g of acetone was added to the reaction solution,Stirring crystallization for 1 hour,Filter the day linen temperature 70g,Dried at 70 Gastrodin dry goods 55g.The products obtained by testing the quality of the indicators are in line with national standards.The obtained product was subjected to HPLC chromatographic detection, The results are shown in Figure 1,Product purity of 99.9673%,The impurity content was 0.0327%.Purity above 99.9%Containing only one impurity below 0.1%Far below the pharmacopoeia standard. |

Chemistry

Chemistry

Pharmaceutical Intermediates

Pharmaceutical Intermediates

Inhibitors/Agonists

Inhibitors/Agonists

Material Science

Material Science

For Research Only

For Research Only

120K+ Compounds

120K+ Compounds

Competitive Price

Competitive Price

1-2 Day Shipping

1-2 Day Shipping