Fractionating Chitin-Glucan Complex and Coproducts from?Pleurotus Ostreatus?Mushrooms

Muhammad Ayser

;

Wafa Tonny

;

Isabella Sanchez Hernandez

, et al.

Waste Biomass Valori.,2023,15,2897-2910.

DOI:

10.1007/s12649-023-02364-5

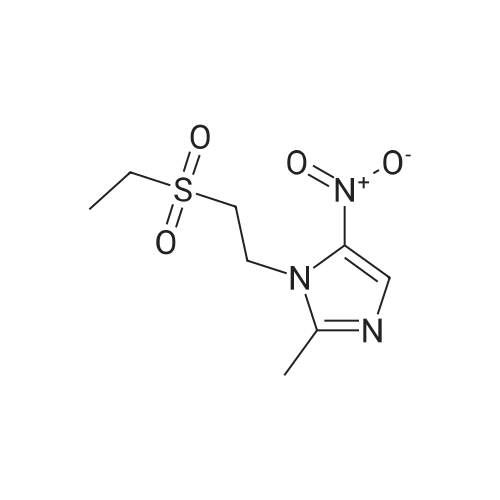

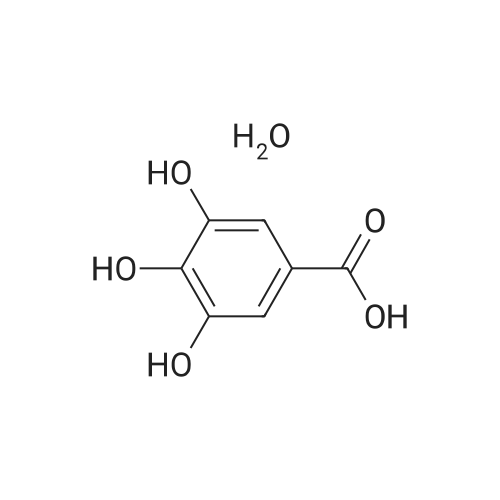

More

Abstract: Purpose: A large amount of wasted mushroom stems are accumulated yearly by the mushroom industry. To reduce this waste, we have proposed a fractionation method to isolate several useful coproducts using reusable solvents. Methods: Coproducts were extracted by sequential solvent extraction before producing chitin-glucan complex from Pleurotus ostreatus (oyster) mushrooms. The extracted β-glucans, polyphenols, and proteins were confirmed by 3,5-dinitrosalicylic acid (DNS), Folin-Ciocalteau, and bicinchoninic acid (BCA) assays respectively. Extracted lipids were analyzed by gas chromatography-mass spectrometry (GC–MS). The chitin-glucan complex was characterized by Fourier-transform infrared spectroscopy (FT-IR), high performance liquid chromatography (HPLC), and powder X-ray diffraction (XRD). Results: The extract yield of chitin-glucan complex was 8.3%. The crystallinity index of the extracted chitin-glucan complex was 71.2% when compared to 85% for crustacean chitin. The reduced crystallinity in mushroom chitin was due to the presence of the residual β-glucans. Conclusion: The reported fractionation method uses less solvent and provides a greener alternative to producing chitin-glucan complex when compared to the conventional methods of using a large volume of harsh chemicals harmful to the environment. Further, fractionating several coproducts while producing the chitin-glucan complex will reduce the total processing cost.

Keywords:

Chitin ;

Chitosan ;

Mushrooms ;

Vitamins ;

Proteins ;

β-Glucans

Purchased from AmBeed:

5995-86-8

Fractionating Chitin and Coproducts from Pleurotus ostreatus Mushrooms

Muhammad Ayser

;

Wafa Tony

;

Isabella Sanchez Hernandez

, et al.

University of Houston,2023.

DOI:

10.21203/rs.3.rs-2916722/v1

More

Abstract: A large amount of wasted mushroom stems are accumulated yearly by the mushroom industry. To reduce this waste, we have proposed a fractionation method to isolate several useful coproducts such as β-glucans, lipids, Vitamin D, polyphenols, and proteins before producing chitin from oyster mushrooms using reusable organic solvents. The extracted β-Glucans, polyphenols, and proteins were confirmed by 3,5-dinitrosalicylic acid (DNS), Folin-Ciocalteau, and bicinchoninic acid (BCA) assays respectively. Extracted lipids were analyzed by gas chromatography-mass spectrometry (GC-MS) and chitin was characterized by Fourier-transform infrared spectroscopy (FT-IR) and powder X-Ray diffraction (XRD). The crystallinity index of the extracted chitin was 71.2% when compared to 85% for crustacean chitin. The reduced crystallinity in mushroom chitin was due to the presence of some β-glucans. Overall, the reported fractionation method uses less solvent and provides a greener alternative to producing chitin when compared to the conventional methods of using a large quantity of harsh chemicals harmful to the environment. Further, fractionating several coproducts while producing chitin will reduce the total processing cost.

Keywords:

Chitin ;

Chitosan ;

Mushrooms ;

Vitamins ;

Proteins ;

β-Glucans

Purchased from AmBeed:

5995-86-8

Chemistry

Chemistry

Pharmaceutical Intermediates

Pharmaceutical Intermediates

Inhibitors/Agonists

Inhibitors/Agonists

Material Science

Material Science

For Research Only

For Research Only

120K+ Compounds

120K+ Compounds

Competitive Price

Competitive Price

1-2 Day Shipping

1-2 Day Shipping