| 90% |

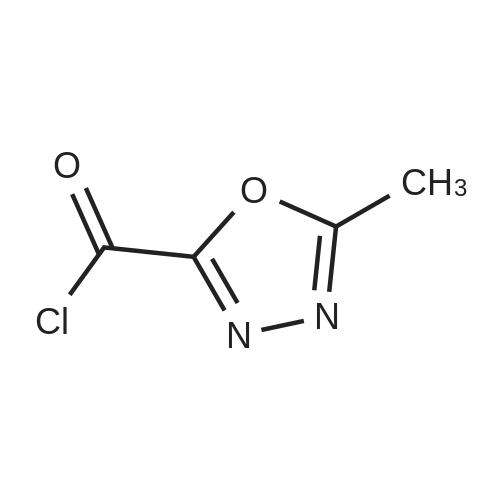

With triethylamine; In acetonitrile; at 50 - 60℃;Inert atmosphere; |

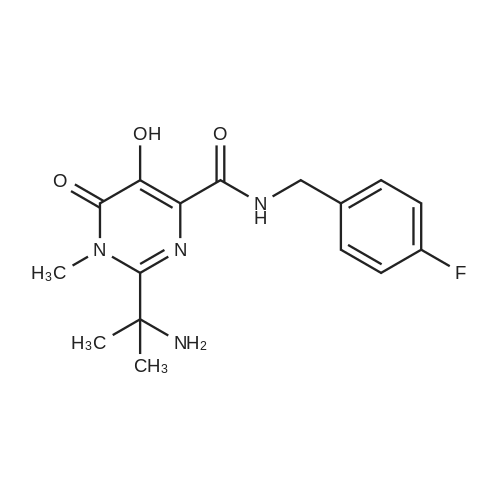

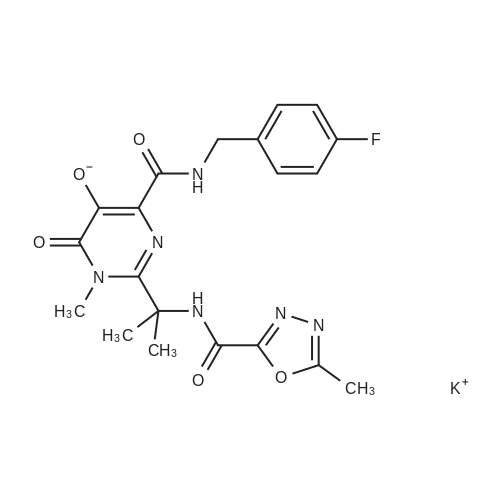

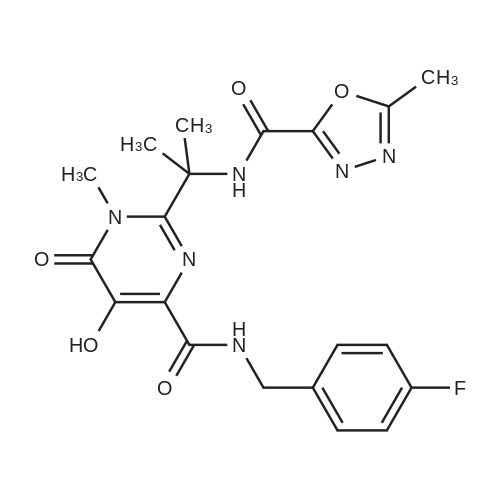

Operating as described in Example 1, but after the catalyst was filtered, NaOH 2M was slowly dripped to reach pH ~ 8 maintaining a temperature lower than 20C, to the solution cooled to about 20C. At completed addition, the product of formula (II) was precipitated in the form of free base, the suspension was maintained at 0-5C for 1 hour, filtered and the solid washed with cold water (2 c 45 ml), dried in vacuum at 60C for at least 6 hours to give the compound of formula (II) free base in hydrated form (26.6 g, KF 4.74%) in 93.4% yield on anhydrous base. A suspension hydrated form of the compound of formula (II) free base (21.3 g, 60.7 mmol) in in toluene (100 ml) was dried by complete distillation up to KF 72.7 mmol) was dripped under nitrogen. The mixture was maintained at 50-60C until completion of the reaction and subsequently cooled to room temperature. Water (45 ml), ethyl acetate(l50 ml) and glacial acetic acid to pH 4-4.5 were added to the suspension. The organic phase recovered by decanting was washed again with water (45 ml) and subsequently concentrated. The suspension was then diluted with EtOH (130 ml), heated to 60-70C for 1 h, cooled to 0-5C and, after 1 h, filtered and washed with cold EtOH. The solid was dried under vacuum at 60C for at least 6 h to give Raltegravir (24.3 g, 54.6 mmol) in 90% yield and 99.8% HPLC purity. |

| 79.2% |

With 4-methyl-morpholine; In acetonitrile; at -5 - 5℃; for 1.5h; |

Compound (Xa) (20 g, 0.057 mole MC: -5%) was suspended in toluene (200 ml), azeotropically dried at reflux temperature and the toluene was completely removed by co-distillation with acetonitrile (20 ml). Acetonitrile (80 ml) and N-methylmorpholine (16.5 g, 0.163 mole) were added to the concentrated mass and the resulting slurry was cooled to -5 to 5C. Oxadiazole-5-methyl-2-carbonylchloride slurry was added to the above slurry at -5 to 5C in -30 min and stirred for lhr at 0-5C. After completion of reaction, acetonitrile was distilled at 50-55C under reduced pressure till total volume of reaction mass became to four volume. After that water (80 ml) was added and the pH of the reaction mass was adjusted to -9.0 with aqueous potassium hydroxide solution. The mass was stirred for 1 hr at 25-30C. Then the pH of reaction mass was adjusted to 4.0- 4.5 with 5N aqueous hydrochloric acid and stirred the mass for 15-min. DM water (120 ml) was added slowly and the resulting slurry was stirred for ~3hrs at 20-25C The product was filtered and washed with mixture of water and acetonitrile (2.5: 1.0, 40 ml) and dried at 45- 50C under reduced pressure to obtain the title compound (I) 20 g. Yield: 79.2%, Purity (By HPLC, by area normalization): -96%. |

|

|

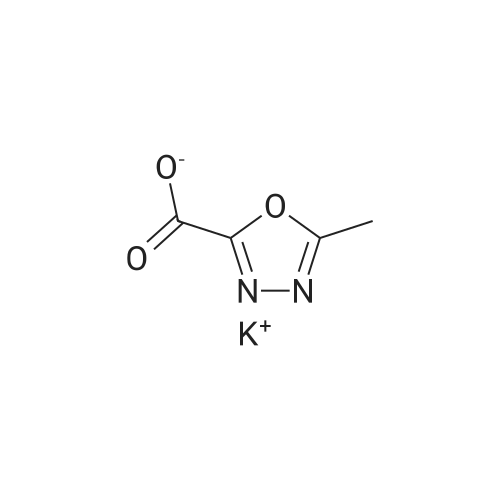

Reagent Mass mL Moles Eq. oxadiazole K salt i 33.8 g (96.1 wt %) 0.20 2.2 MeCN 280 mL DMF 0.33 oxalyl chloride 23.7 g 16.3 mL 0.19 2.1 free amine h 30 g (99 Wt %) 0.089 1 THF 821 mL NMM 21.56 g 23.4 mL 0.21 2.4NH4OH (30% in H2O) 62.3 g 69 mL 0.53 6 HCl (2N) 500 mL IPA 920 mL water 400 mL MeOH 300 mL A 500 mL round bottom flask was charged with oxadiazole K salt i (33.8 g) followed by MeCN (280 mL) and DMF (0.33 mL) with strong stirring. The resulting slurry was then cooled down to 0-5 C. and oxalyl chloride (23.7 g) was added over the course of 20 minutes in order to maintain the internal temperature at less than 5 C. The resulting acyl chloride-containing slurry was then aged for 1 hour. To a 2 L round bottom flask the free amine h (30 g) was added followed by THF (821 mL). The resulting slurry was cooled down to 0-5 C., after which NMM (21.56 g) was added and the slurry so obtained was stirred for 10 minutes at the cold temperature. The previously prepared acyl chloride-containing slurry was added slowly to the free amine slurry over the course of 20 minutes such that the temperature did not exceed 5 C. The slurry was then aged for 1.5 hours at 0-5 C. At this time HPLC showed no more amine h (<0.5% LCAP, 100% conversion). The reaction mixture was then quenched with NH4OH (30% in water) (69 mL) which was added over the course of 3 minutes. The resulting yellow slurry was then stirred for an additional hour at temperatures less than 10 C. The yellow slurry was then acidified to pH 2-3 with HCl (2N) (500 mL). To the resulting red wine colored solution, IPA (920 mL) was added. The low boiling point organic solvents were then evaporated under reduced pressure (40 torr) at room temperature to a final solution volume of 1100 mL, at which volume crystalline Compound A began to precipitate. Water (400 mL) was then added to this new slurry over the course of 10 minutes, and the slurry aged overnight at room temperature. The aged slurry was filtered and the solid obtained was washed with water (170 mL), followed by a swish wash with cold MeOH (300 mL, previously cooled in an ice bath), and finally by a swish wash with water (700 mL). The solid so obtained was dried overnight under vacuum and nitrogen stream to give 35.5 g of Compound A (91% yield). |

|

|

A 500 mL round bottom flask was charged with oxadiazole K salt i (33.8 g) followed by ACN (280 mL) and DMF (0.33 mL) with strong stirring. The resulting slurry was then cooled down to 0-50C and oxalyl chloride (23.7 g) was added over the course of 20 minutes in order to maintain the internal temperature at less than 50C. The resulting acyl chloride-containing slurry was then aged for 1 hour.To a 2 L round bottom flask the free amine h (30 g) was added followed by THF (821 mL). The resulting slurry was cooled down to 0-50C, after which NMM (21.56 g) was added and the slurry so obtained was stirred for 10 minutes at the cold temperature. The previously prepared acyl chloride-containing slurry was added slowly to the free amine slurry over the course of 20 minutes such that the temperature did not exceed 5 0C. The slurry was then aged for 1.5 hours at 0-50C. At this time HPLC showed no more amine h (<0.5 % LCAP, 100% conversion). The reaction mixture was then quenched with NH4OH (30 % in water) (69 mL) which was added over the course of 3 minutes. The resulting yellow slurry was then stirred for an additional hour at temperatures less than 1O0C. The yellow slurry was then acidified to pH 2-3 with HCl (2N) (500 mL). To the resulting red wine colored solution, IPA (920 mL) was added. The low boiling point organic solvents were then evaporated under reduced pressure (40 torr) at room temperature to a final solution volume of 1100 mL, at which volume EPO <DP n="35"/>crystalline Compound A began to precipitate. Water (400 mL) was then added to this new slurry over the course of 10 minutes, and the slurry aged overnight at room temperature. The aged slurry was filtered and the solid obtained was washed with water (170 mL), followed by a swish wash with cold MeOH (300 mL, previously cooled in an ice bath), and finally by a swish wash with water (700 mL). The solid so obtained was dried overnight under vacuum and nitrogen stream to give 35.5 g of Compound A (91% yield). |

| 115 g |

|

A mixture of oxadiazole K-salt Va (79.5 g, 0.478 mol), acetonitrile (400 ml), and DMF (2.47 ml) was cooled to -5 C and oxalyl chloride (38.4 ml, 0.448 mol) is added over a course of 30 min. The resulting slurry was aged at 0-5 C for lh, then cooled to -10 C. (0151) A slurry of amine lib (100 g, 0.299 mol) and THF (1L) was stirred at room temperature and HMDS (49.5 ml, 0.239 mol) is added dropwise over a period of 5 min. To the resulting suspension 1.71g p-TsOH (8.9 mmol) were added in one portion. The reaction mixture was heated at 60-65 C for 2h, then cooled down at -5- (0152) 0 C and N-methylmorpholine (98.8 ml, 0.898 mol) was added. The resulting solution was aged at -5 C for 20 min. The oxadiazole acid chloride Va was added dropwise to the amine containing slurry reaction mixture at -5 C over a course of 45 min. Reaction is monitored with HPLC and after completion 20% aq. potassium hydroxide (500 ml) was added and the reaction mixture is stirred at 5 C for lh. HC1 2N (370 ml) was added over 10 min to adjust pH at 3-4 and reaction mass is warmed at 15 C. 3.75 L ml water were added slowly over a course of lh. The resulting white suspension was aged at 15 C for 1 h and filtered. The cake was washed with 300 ml water/acetonitrile (2.5: 1) and 300 ml water. White solid is dried to afford Raltegravir (0153) 1 (115 g, 0.258 mol). (0154) 1H-NMR (500 MHz, DMSO-d6) delta 12.21 (s, 1 H), 9.86 (s, 1H), 9.08 (t, J = 6.4 Hz, 1 H), 7.41-7.38 (m, 2 H), 7.19-7.15 (m, 2 H), 4.52 (d, J = 6.4 Hz, 2 H), 3.49 (s, 3 H), 2.56 (s, 3 H), 1.74 (s, 6 H). (0155) 13C-NMR (125 MHz, DMSO-d6) delta 168.4, 165.7, 162.2, 160.3, 158.5, 158.1, 152.6, 151.8, 145.7, 134.9, 129.5, 124.4, 115.2, 57.6, 41.6, 32.9, 27.0, 10.7. |

Chemistry

Chemistry

Pharmaceutical Intermediates

Pharmaceutical Intermediates

Inhibitors/Agonists

Inhibitors/Agonists

Material Science

Material Science

For Research Only

For Research Only

120K+ Compounds

120K+ Compounds

Competitive Price

Competitive Price

1-2 Day Shipping

1-2 Day Shipping