Silicone Pad Printing IOTA-L610

| Price | $5.97 |

| Package | 200kg |

| Min. Order: | 1000kg |

| Supply Ability: | 800 tons per month |

| Update Time: | 2024-12-16 |

Product Details

| Product Name: Silicone Pad Printing IOTA-L610 | Min. Order: 1000kg |

| Purity: 99.9% | Supply Ability: 800 tons per month |

| Release date: 2024/12/16 |

- Pad printing silicone is professionally used in the manufacture of pad printing heads. Using silica gel as a carrier to transfer the pattern on the steel plate to the product is called pad printing. Pad printing glue head is to use the picture on the steel plate as a carrier through the glue head, and then transfer the picture on the steel plate to the toy product to print irregular pictures and so on. Pad printing silica gel for electronic goods is a fluid liquid pad printing glue that is divided into components A and B. It can be prepared as a pad printing elastic material with excellent performance, which has excellent durable grinding performance, non-deformation and good ink transfer performance.

Application:

The main application fields of pad printing paste for electronic products are high-end precision electronic accessories, electronic toys, craft gifts, electronic products with fine lines, printing of irregular pictures and silk screen printing of trademarks, etc.

Advantages :

1. Low viscosity and good fluidity

2. No shrinkage, good oiling, clear printing images

3. Fine glue, good resilience, and many times of pad printing

4. No impurities, no particles, good resilience, high-quality rubber material for pad printing silicone

Production steps:

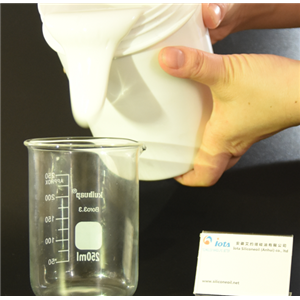

1. Clean the plastic head mold completely, apply mold release agent, and place it in a balanced place;

2. Pour the pad printing paste and silicone oil into the measuring cup according to the proportion and stir evenly, then add the curing agent and then mix thoroughly and evenly;

3. Slowly pour the evenly mixed silica gel into the rubber ;

4. Cover the board, the plastic head can be demolded after 3-4 hours.

Instructions for the use :

1. This product is stored at room temperature, in a dry bath and in a sealed container. Do not contact with water to prevent deterioration.

2. The service life of the pad printing head is closely related to the size of the pattern to be printed. In the pad printing operation, the head should be replaced according to the size of the pattern. For example, if a large pattern is printed, a larger pad printing head should be used; if a small pattern is printed, a small head should be used. If printing large patterns and thick fonts, use a pad printing head with less hardness; on the contrary, if the pattern is small and fine, choose a soft pad printing head.

3. The distance between the ink printing plate and the pad printing pad determines the maximum size of the pad used. The key to achieving a good pad printing effect is to reduce and control many variable factors in pad printing. In general, the harder the pad, the better the performance; the larger the pad, the less image distortion occurs.

Company Profile Introduction

Iota Silicone Oil (Anhui) Co., Ltd was located in Bengbu, Anhui Province, which is the manufacturing operation of Iota Corporation Limited in China. As a leading supplier in organic silicon industry, silicon-based technology and innovation area, IOTA provide the whole industry chain silicone performance solutions. We serve the market in various fields, covering textiles and leather, food and beverages, paints, oil and natural gas, cosmetics, electronics, aerospace, automotive, construction, medical care, casting, personal care, agriculture, and LED.

Iota Silicone Oil maintains close long-term cooperative relationship with many universities and research institutes in Nanjing and implements a strict and complete quality control system, which ensures that each product can meet quality requirements of customers. Besides, all of our products have been strictly inspected before shipment. Technical support and scientific management of the powerful can provide all kinds of high quality organic silicon materials for our customers.

Recommended supplier

| Product name | Price | Suppliers | Update time |

|---|

- Since: 2022-04-14

- Address: Bengbu, Anhui

INQUIRY

Zhang

+86-15255260163

sales05@siliconeoil.net

+86-15255260163

sales05@siliconeoil.net

China

China