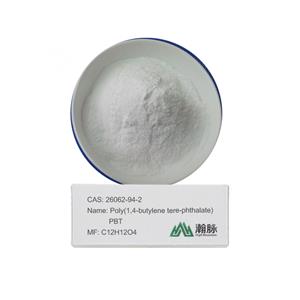

Poly(1,4-butylene tere-phthalate) NEW

| Price | Get Latest Price | ||

| Package | 25Kg Paper Bag | 50Kg Paper Bag | 100Kg Paper Bag |

| Min. Order: | 1000Kg Paper Bag |

| Supply Ability: | 100 Metric Ton/Metric Tons per Year |

| Update Time: | 2025-01-08 |

Product Details

| Product Name: Poly(1,4-butylene tere-phthalate) | CAS No.: 26062-94-2 |

| EC-No.: 607-857-5 | Min. Order: 1000Kg Paper Bag |

| Purity: / | Supply Ability: 100 Metric Ton/Metric Tons per Year |

| Release date: 2025/01/08 |

Basic Information

Model Number : HMHT0169

Product Parameters

| Product Usage | Used In The Manufacture Of Various Components Such As Instruments, Electrical Appliances, Televisions, Machinery, Etc. |

| Wgk Germany | 3 |

| Upstream Raw Materials | Antimony Trioxide Decabromodiphenyl |

| Downstream Products | Antimony Trioxide Antimony Trioxide Decabromodiphenyl |

Packaging Types

25KG CRAFT PAPER BAGS or as per customers' requirement

Storage Information

Keep in a cool, dry, dark location in a tightly sealed container or cylinder .

Applications

PBT is known as one of the engineering plastics with excellent comprehensive performance. It is widely used in electrical, electronic, automobile, machinery, instrumentation and other industries as structural parts, such as coil skeletons, connectors, bases, etc. for TVs and radios. Suitable for structural parts that require lubricity and corrosion resistance, such as gears, bearings, etc. After the flame retardancy of PBT is enhanced, its performance is further improved, and it has more important uses in the above fields (see the section on the use of glass fiber reinforced PBT).

Chemical properties

The relative density is 1.31-1.55, and the water absorption rate is the lowest among thermoplastics, only 0.07%. It has excellent toughness and fatigue resistance, high impact strength, self-lubrication and wear resistance, small friction coefficient, but high notch sensitivity. Good heat and weather resistance, flame retardant, but slow burning. Good dimensional stability, excellent electrical properties, and good arc resistance, but the volume resistivity and high-frequency dielectric loss tangent are large. Excellent chemical resistance, alcohol, aliphatic hydrocarbon, acid and salt aqueous solution, etc. do not work. Resistant to carbon tetrachloride, swells in dichloroethane, somewhat swells in aromatics, acetic acid and ethyl acetate, decomposes in concentrated nitric acid and sulfuric acid. It is resistant to hot water and oil, but it is easily corroded by halogenated hydrocarbons and has poor hydrolysis resistance. Low melt viscosity, excellent film forming and formability, but large shrinkage, good film flexibility, high tear and yield strength. PBT molding can be injection molding, extrusion, blow molding, coating, welding, bonding, machining, vacuum forming, vacuum metallization, coating, etc.

Company Profile Introduction

You may like

Recommended supplier

| Product name | Price | Suppliers | Update time | |

|---|---|---|---|---|

| $8.00/1KG |

VIP2Y

|

Henan Fengda Chemical Co., Ltd

|

2024-04-08 | |

| $1.10/1g |

VIP4Y

|

Dideu Industries Group Limited

|

2022-07-18 | |

| $1.00/1KG |

VIP6Y

|

Career Henan Chemical Co

|

2020-01-31 |

- Since: 2014-04-15

- Address: Room 1815, No. 1008, Jiefang East Road, Wuxi

China

China